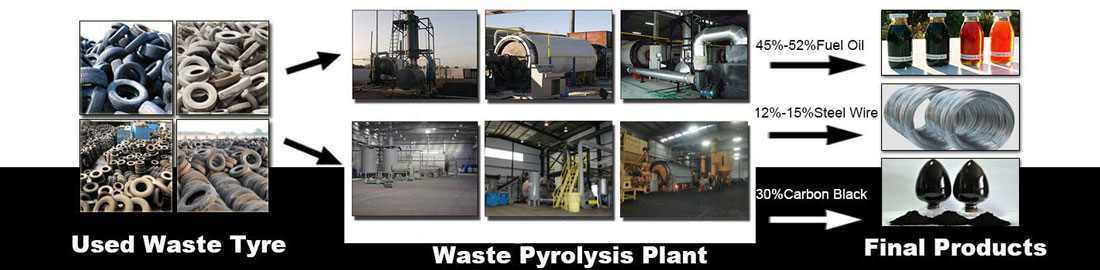

In order to effectively deal with waste tires and create more profits, our company has manufactured a new type of waste tyre recycling plant. The plant mainly has the following advantages:

1. Advanced technology and useful final products

Our waste tyre recycle plant has adopted the most advanced pyrolysis technology, which can effectively convert waste tires into about 45% fuel oil, 35% carbon black and 15% steel wire. All the final products are useful resources and have wide applications. The pyrolysis oil from tyres can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for making construction bricks with clay or used as fuel. The steel wire can be re-sale or reprocessing. All the end-products are in high demand and sell well in the market, which will surely bring you benefits.

2. High oil output rate

As a professional pyrolysis plant manufacturer, we have two special methods to improve the oil yield. Firstly, compared with general condensers, our tubular condenser has the features of larger cooling area and better cooling effect, which can greatly improve the oil yield. Besides, it is easy to maintain, which is very convenient for customers. Secondly, we can provide special catalyst, which is made from 24 chemicals. The catalyst not only reduces sulfur content and density of oil, but also improves its flavor and color.

Waste Tyre Recycling Plant In Jordan Video:

Ensuring safety in production is our principle. Hydroseal and vacuum system will prevent exhaust gas from going back to condensers and reactor. Thus, unnecessary accident can be avoided. In addition, the plant is equipped with safety device (alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system, fire fighting devices), which can avoid danger in the production process and guarantee safety.

4. Features of energy-saving and environmental protection

Firstly, in the waste tyre pyrolysis process, some combustible gas can not be converted into oil liquid in normal temperature and pressure, which could be recycled to the bottom of the reactor for reheating through the pipe of tail gas. In this way, it can avoid the gas contamination and save the fuel energy.

Secondly, in the system, three steps are used to dedust the hot smoke from reactor, more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged in the air directly.

Beston Pyrolysis Plant Types:

| Model | BLJ-6 | BLJ-10 | |

| Daily Capacity | 6T | 8-10T | |

| Working Method | Batch | ||

| Raw Materials | Waste Plastic, Tyre, Rubber, Oil Sludge | ||

| Reactor Size | D2.2*L6.0m | D2.6*L6.6m | |

| Pattern | Rotary | ||

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. | ||

| Total Power | 24kw/h | 30kw/h | |

| Floor Area (L*W*H) | 30*10*8m | 30*10*8m | |

| Service Life | 5-8 Years | ||

| Model | BLJ-16 |

| Daily Capacity | 15-20T |

| Working Method | Semi-Continuous |

| Raw Materials | Waste Plastic, Tyre, Rubber, Oil Sludge |

| Reactor Size | D2.8*L7.1m |

| Pattern | Rotary |

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. |

| Total Power | 54kw/h |

| Floor Area (L*W*H) | 40*10*8m |

| Service Life | 5-8 Years |

| Model | BLL-20 |

| Daily Capacity | 20-24 T |

| Working Method | Fully Continuous |

| Raw Materials | Waste Plastic, Tyre, Rubber, Oil Sludge |

| Reactor Size | D1.4*L11 m |

| Pattern | Horizontal |

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. |

| Total Power | 71.4kw/h |

| Floor Area (L*W*H) | 45*25*10m |

| Service Life | 5-8 Years |