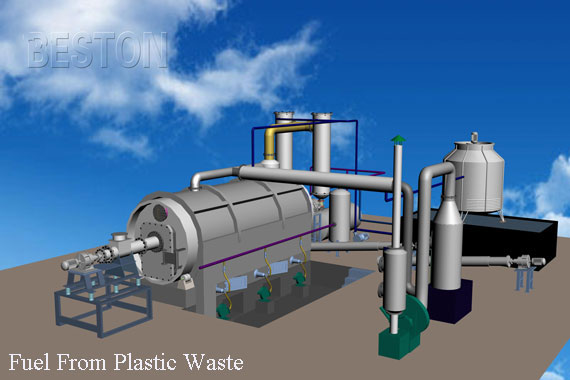

In order to maximize the recycling of waste plastics and convert them into fuel energy, we have designed the plastic to fuel machine. With 17 years’ efforts, our plants are already quite mature in the international market now.

The plant adopts the pyrolysis technology by which waste plastics can be converted into fuel. The fuel from plastic waste mainly includes plastic oil and carbon black, and they have a wide application in many fields. For example, the fuel oil from plastic waste can be used as industrial fuel materials for burning, or further refined to diesel or gasoline. The carbon black can be used for making construction bricks with clay or used as fuel. You will surely benefit a lot from the end products.

So we have two special methods to improve the average fuels from plastic wastes yield efficiency, thus creating more benefits for customers. Firstly, we adopt new-type tubular condenser which has larger cooling area and better cooling efficiency. Compared with the general condenser, it can further ensure and improve the oil yield efficiency by 5%. Secondly, we use the special catalyst which is made from 24 chemicals. The catalyst can not only reduce sulfur content and density of oil, but also improve its flavor and color.

Besides, our waste plastic to fuel plant is equipped with mature safety devices (alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system, fire fighting devices), which will avoid danger and guarantee safety in the production process. In the dedusting system, three steps (dust chemical removing tank, ceramic ring filtering system and alkali sprayers) are used to dedust the hot smoke from reactor, more than 95% of the dust would be removed. So, the released gas is pollution-free and can be discharged in the air directly.

So far, we have exported our plants to more than 20 countries and we have won a good reputation from our customers. If you want to buy our plants, please contact us online or send us an email. We will reply you within 24 hours.

| Model | BLJ-6 | BLJ-10 | BLJ-16 | BLL-20 |

| Daily Capacity | 6T | 8-10T | 15-20T | 20-24T |

| Working Method | Batch | Semi-Continuous | Fully Continuous | |

| Raw Materials | Waste Plastic, Tyre, Rubber, Oil Sludge | |||

| Reactor Size | D2.2*L6.0m | D2.6*L6.6m | D2.8*L7.1m | D1.4*L11m |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Fuel Oil, Natural Gas, LPG, etc. | |||

| Total Power | 24kw/h | 30kw/h | 54kw/h | 71.4kw/h |

| Floor Area (L*W*H) | 30*10*8m | 30*10*8m | 40*10*8m | 45*25*10m |

| Operating Pressure | Normal Pressure | Constant Pressure | ||

| Cooling Method | Water Cooling | |||

| Service Life | 5-8 Years | |||