The technical parameters that influence pyrolysis process are the following categories:

1. Pyrolysis temperature. The final products distribution and yield after thermal decomposition are different from the temperature of thermal decomposition. Even for the same pyrolysis feedstock, the composition of the end-products differs greatly due to the different pyrolysis temperatures. The higher the decomposition temperature, the greater the proportion of gas in pyrolysis products, and the combustible oil, solid carbon residue corresponding reduce; in addition, the gas composition also changes with temperature, the higher temperature, the more low molecular weight carbides, CH4, H2 and son on; correspondingly, the composition of the solid residue also changes with temperature.

2. Heating rate. Heating rate has a great influence on the production of pyrolysis. The ratio of the components in the pyrolysis products can be controlled by the combination of the heating temperature and the heating rate. Under the condition of low temperature and low speed heating, the organic molecules have enough time to break down at their weakest chemical bond junction and then recombine to thermosetting solid compound, which is difficult to further decompose, so the solid content in the product increases; while under the condition of high temperature and high speed heating, the molecular structure of the organic compounds has been completely cracked, resulting in a large number of low molecular organic compounds and the gas components of pyrolysis products increases.

3. Moisture in the garbage. Due to the presence of the evaporation heat, the moisture content of the waste is clearly related to the rate of the energy recovered and the temperature that can eventually reach. If the garbage moisture is large, it needs a lot of auxiliary fuel because the heat can not reach the balance, and the steam will affect the proportion of various products in the gasification process. As the water vapor and carbon and carbon dioxide will occurs water gasification reaction, it makes the carbon content in the residue reduce and the proportion of hydrogen and carbon monoxide in the gas increase.

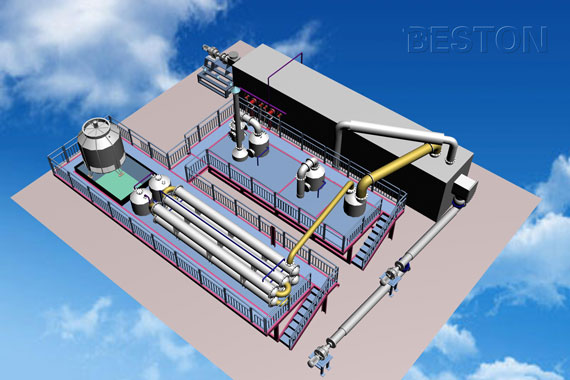

4. Types of pyrolysis unit. Pyrolysis reactor is where the pyrolysis reaction occurs and is the key to the whole pyrolysis process. Different pyrolysis reactors have different ways of feeding and discharging. Beston has developed two types of pyrolysis furnaces available for your choice, 360-degree rotary and stable.

5. Supply of oxygen. As the oxidizing agent in the pyrolysis reaction, air or oxygen makes the materials part of combustion to provide thermal energy and guarantee the pyrolysis reaction. Therefore, the supply of adequate air or oxygen is very important and also needs to strictly control.